About us

Anhui shengtai heavy industry machinery manufacturing co., l...

Welcome To Anhui Shengtai Heavy Machinery Manufacturing Co., Ltd.

中Hotline:18155505798

Date: 2018-11-05 Views: 728

|

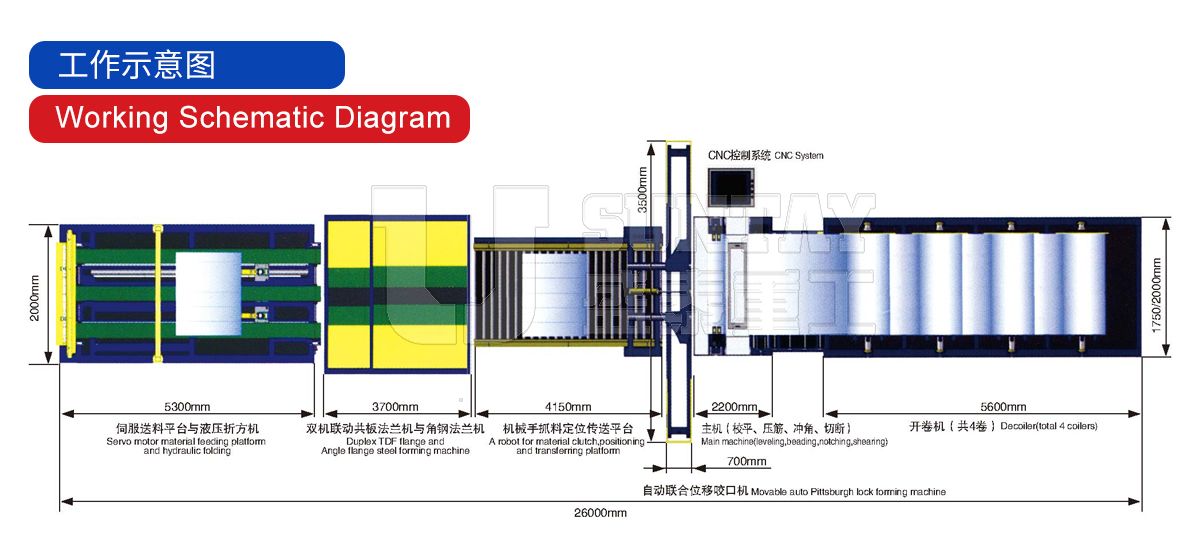

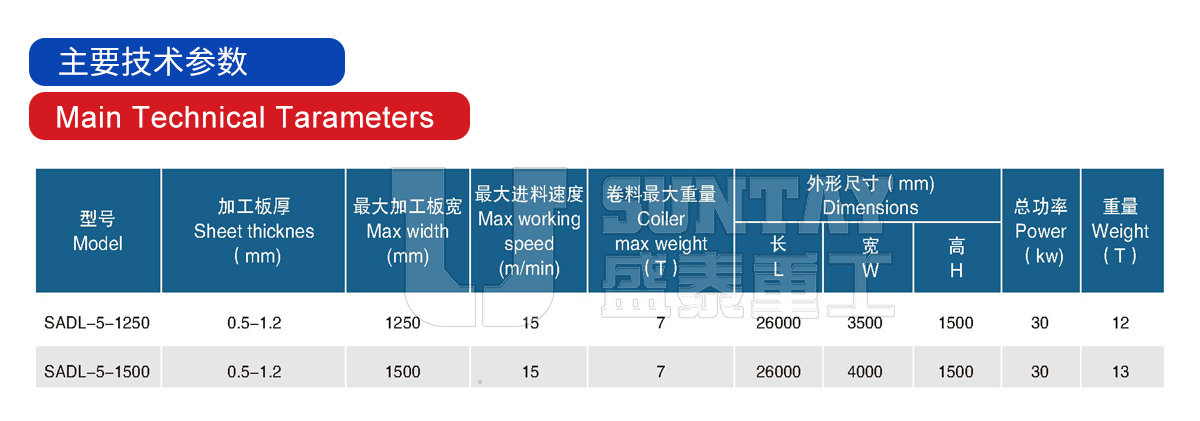

Function It’s mainly for TDF/angle steel/C-shaped flange forming with daily processing capability of 600-2000 square meters. Only with inputting dimensions in duct, production line can automatically complete uncoiling, leveling, beading, punching, shearing, locking, forming TDF/angle steel/C-shaped flange and folding.

Performance Features 1: The linear structure of machine makes processing smoothly and occupies a small Space. 2: All the rolling reels are made of bearing steel so that the lifetime prolongs by more than 5 times. 3: Under the material-saving mode of CNC system, waste is less than 20mm per roll. 4: The injection holes are used at both ends of the drive shaft, to enhance the bearing life. 5: Power bending function is used to prevent generating the waste and make sure perfect bending accuracy. 6: It requires at least one person to operate and each shift can output 600-2000㎡. 7: With production memory functions, the production orders can be tracked and checked.

Main Import Configuration 1: Cylinder imported from Germany Festo 2: Hydraulic system imported from Taiwan 3: Japan Omron encoder 4: Taiwan Hiwin linear guideways 5:Taiwan Delta CNC system

Basic Configuration 1: Two electric coil cradles, 4 material trays (5-7t each roll) 2: One rack 3: One host (line 2 host) 4: One mechanical arm clutching, locating and transferring platform 5: One displacement type locking machine 6: One duplex TDF flange forming machine 7: One duplex angle steel flange forming machine 8: One servo feeding platform 9: One hydraulic folding machine 10: One set of computer controlling system |